CAC®

Our proprietary process ensures particle and dent free copper surfaces.

The best and most economical solution for using difficult-to-handle thin foils, reverse treated and double treated copper foils.

Light Gauge Metal Toll Processing

At CAC we say that “our specifications are your specifications” because we excel at running the lighter gauges and more difficult time-consuming jobs for correct flatness issues that other larger roll levelers cannot. Contact us today to see how CAC can overcome your metal processing challenges.

Solid Aluminum

Solid aluminum foil is used as a drill entry material or lamination grade separator sheet in PCB applications. Burr free holes begin with solid aluminum foil. Panel after panel, hit after hit, solid aluminum will enable the drilling of consistent, high quality holes, enhanced productivity and an improved bottom line.

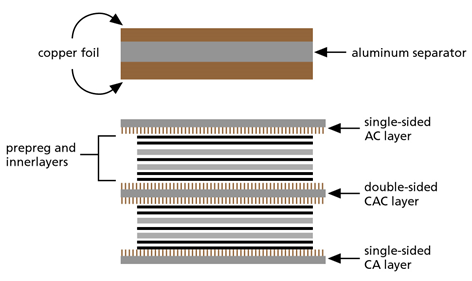

CAC, Inc. is a manufacturer of CAC® (Copper Aluminum Copper). Our licensed and patented product features copper foil attached in our 'state-of-the-art' clean room to one or both sides of an aluminum separator sheet based on the customer's requirements. CAC® provides superior surface quality important to producers of high technology printed circuit boards, as well as total process and labor cost savings.

CAC Benefits

Aluminum CTE is greater than Copper and prepreg resins ensuring a wrinkle free surface.

No separators to clean resurface or polish which are labor intensive & costly.

Image impressions & FOD concerns minimized with all 4 edges being bonded.

Gained by reducing the overall book mass to heat AND cool in a cycle.

Supporting thin & low-profile Copper foils from 6 µm > with a VLP2 or IPC A profile.

A bonded Aluminum product in Top and Bottom and or middle configuration, with a single layer of your desired copper foil bonded to the aluminum carrier.

CAC® Advantages

Global Distribution Network

CAC, Inc. partners with the best PCB material distributors in the world and is ready to meet your CAC® needs throughout North America, Europe, and Asia.